Click here to read the May 2022 issue of The Flimsy Board from the Bremerton Northern Model Railroad club.

You are browsing archives for

Category: Articles

How to’s, presentations, and informational articles

Puget Sound Garden Railroading March 2022 Newsletter

Click here to read the March 2022 issue of The PSGRS Newsletter from the Puget Sound Garden Railroading Society.

Bremerton Northern March 2022 Flimsy

Click here to read the March 2022 issue of The Flimsy Board from the Bremerton Northern Model Railroad club.

David Yadock’s Dry Gulch & Western Update 10

Article & Photos By David Yadock

Dry Gulch & Western, Update 10

It has been a while since my last update. I thought I would do a little different update this time. Instead of reporting on scenery progress I would report on other items taking place on the Dry Gulch & Western. There have been several additions to my locomotive fleet. All of these have been either re-builds of Ebay specials or in one instance a modification of an old AHM model. I believe more folks should take this approach for adding to their own fleet of locomotives. All it takes is some time, patience, and a few choice tools.

I have been very busy updating and weathering my freight cars. The corresponding car cards have had photos of their respective car added to them. This has been a monumental task since I have well over 200 freight cars on the layout at any given time. Now all my freight cars on the layout have some form of weathering applied to them. Operators on the layout can easily find a specific freight car since they have a reference photo of the car on the front of the car card. I admit I stole this idea from Jim Younkins!

In this photo you can see the end product that was produced from another of my basket case purchases off of Ebay. This is a model of a PFM UP 2-8-0 locomotive. I’m not quite sure what the previous owner did to this locomotive, but the drivers were not in quarter. The tender was missing a wheelset and the back convex portion of the Vanderbilt tender tank was missing. I admit I have dealt with worse off locomotives but this one was in sad shape. I replaced the gearbox and motor. I installed a new motor mount, motor, and driveline. The drivers were checked for gauge and re-quartered. The cool thing about this re-build was that I could install a DigiTrax sound decoder and Stay Alive system in the tender since the back was missing. I did install new wheelsets on both tender trucks. I only needed to enlarge the holes on the tender trucks to accept the new wheelset axles. For the rear convex section of the tender, I found an old plastic Roco tank car that gladly accepted the challenge to be the donor. I was able to saw off the convex portion of the Roco tank. It almost fit perfectly into the tank of the tender. I did need to remove about 1/16” of the bottom for it to slide into the tender tank. I added a couple of stops onto the inside of the tank to keep the new convex section positioned correctly. I lightly glued it in place with Walthers Goo once the decoder was installed. The new tender back is easily removeable by gently prying it away from the tender tank wall if the decoder needs repair. Yes, it isn’t all constructed from brass, but the new paint job hides this deception very well.

This locomotive began its life as a model of a SP C-8 2-8-0. The manufacturer is unknown. I bought it many years ago on Ebay without a tender. The locomotive had some issues since the motor was an open frame type and the gearbox/driveline was completely shot. This time the drivers were in quarter! I had an extra PFM ATSF 2-8-0 tender that was a separate Ebay purchase, so I mated the two together and produced this model. The model had a Mabuchi can motor installed with a custom mount. A new driveline was fabricated and a new NWSL gearbox was installed. This locomotive, like all my other locomotives, had several modifications. A DigiTrax sound decoder and Stay Alive capacitor system were installed. A firebox LED light, working front headlight, and working rear backup light were also installed. This old model was brought back to life and will be working on my layout for many years to come.

I bought this model of a PFM ATSF 2-8-0 years ago at the Boeing Employees swap meet. It was a good price and thought it would be an excellent model to run on my layout. It had already been painted, but the paint was way too gray. Even the valve gear had the same gray paint! The coloration didn’t look right. I did the normal modifications on this locomotive to make it DCC compatible. Again, a Mabuchi can motor was installed with a custom motor mount. A NWSL gearbox was installed with a new driveline. I installed a DigiTrax sound decoder and Stay Alive system in the tender. A “sugar cube” speaker was attached to the back portion of the boiler weight. It fit very well in that location and produces nice sound. A firebox light, front micro LED headlight, and micro LED back up light were installed. Of course, the locomotive was repainted and lettered for the Dry Gulch & Western.

This locomotive started out as an AHM (Rivarossi) model of the famous B&O 0-4-0 Docksider locomotive. The locomotive in an unmanipulated form is a fine model if your layout has code 100 track and is not DCC! I liked this locomotive from the first time I saw it back in the 1970’s, that is why I bought it back then. I have always wanted this locomotive to be able to run on my layout. Now was the time to make some changes. My standard Mabuchi can motor was too large to fit in the locomotive without creating a custom driveline. I decided to use a smaller micro-can motor to fulfill the installation. Yes, this motor only has an 8-volt power rating, but it can be used to power this locomotive. Since this locomotive is relatively small, realistically it can’t pull a large string of freight cars, so this tiny motor will not be overtaxed. To use this motor, you only need to adjust your voltage output settings on your decoder to 6 volts. I used the original worm gear and bull gear located on the driver. I installed the old worm gear onto the new motor shaft by making a custom coupling. The original motor mount was used to mount the new motor. The wheel flanges were carefully filed down to the correct depth to allow this locomotive to run on even code 55 rail. A small Tsunami Econami sound decoder and the new Keep Alive 2 system was installed. The tiny “sugar cube” speaker was attached to the interior of the cab. Both front headlight and rear back up lights use micro-LEDs. A 5mm flicker Led was installed next to the motor to act as a firebox light. This will make for a nostalgic addition to my layout!

These photos are specifically for Al Lowe! They are proof of what can be done with an inexpensive old freight car. At the last Boeing Employees swap meet I bought one of these cars (Photo 59) and Mr. Lowe was intrigued by my suggested use. I already had 2 copies of this same car that were originally produced by Tyco and bought decades ago (Photo 58). They both had a strange cradle designed to carry large diameter pipe sections. I liked the short length of the car and thought they could be used as transport flats for my granite mine. I didn’t have to do much modification to them. I added some wooden decking over the odd cradle section, a brake staff, and some foot stirrups. Some weathering and a couple of chunks of “home-made” granite completed the car set. Of course, they received metal wheelsets and Kadee #5 couplers.

I thought I would present some of my “other” projects to show that you can make a silk purse out of a sow’s ear. Sometimes you encounter freight cars that really aren’t very detailed or have features that are not desirable for your intended purpose. Don’t give up on them! Just because they look odd or have strange features that doesn’t mean they can’t be modified to fit your needs. Yes, these projects do require some work, but this allows you to create a car that is more customized than the standard “off the shelf” cars. This is part of the fun. Next time I’ll get back to my scenery projects. The town of Dry Gulch is nearing completion and my expansive alcove section of the layout is having scenery applied at a record pace.

David

Bremerton Northern February 2022 Flimsy

Click here to read the February 2022 issue of The Flimsy Board from the Bremerton Northern Model Railroad club.

Bremerton Northern January 2022 Flimsy

Click here to read the January 2022 issue of The Flimsy Board from the Bremerton Northern Model Railroad club.

David Yadock’s Dry Gulch & Western Update 9

Article & Photos By David Yadock

Dry Gulch & Western, Update 9

In the last update you were able to see the new access hatch that was placed in the town of Dry Gulch. For this update, I’ll show you how it works and how this type of hatch makes life a lot easier when conducting maintenance. I would assume that there is some interest in its construction and operation.

Most modelers use a variety of ways to gain access to areas of their layout that is inaccessible from an aisle. The most common type is the simple “lift-out” hatch, this type is a simple cover to a hole in the layout. These are easy and quick to construct but difficult to actually use. One must usually find a place to put the hatch while doing maintenance.

My sliding hatch operates using a simple 1 x 4 pine board that is housed in a shaft built from four pine boards of the same size. It uses a single L-shaped lift mechanism for simplicity. Since the weight/size of the hatch is not too heavy only a single lift support is used. When raised, the hatch is held in place with a nail. A hole was drilled at a desired height completely through the shaft and hatch support. A wide pen mark on the support rails notifies the user when full extension is achieved.

Photo 47 shows the access hatch fully extended to allow access for maintenance. You will also note that the access hole is rather large to allow easy movement for maintenance. This was necessary since there are several locations on all sides of the hatch that require maintenance access.

Photo 48 gives you an idea of the simple construction of the shaft. The shaft is not completely enclosed. This was done to save on wood and remove any possible binding issues of the hatch support.

Photo 49 is a close-up of the nail placement. This nail goes completely through the hatch support and shaft enclosure to ensure the hatch will not inadvertently drop down.

Photo 50 shows the line drawn on the hatch support. This acts as a guide when pushing the nail into the hole.

Photo 51 shows a trick I used to hide the hatch seam that runs along a roadway. I glued the back wheels of a large box van type truck to one side of the roadway that is on the hatch. The other side of the truck’s wheels are not glued down. This large truck straddles the seam and hides it quite well!

Photo 52 shows the hatch back in place. The dangling box truck from photo 47 is now back at rest on the roadway! Notice how that box van helped hide an offending seam.

Photo 53 has Santa on his way!

In the next update I’ll show you the new scenery additions to Dry Gulch. Progress is being made on the locomotive service facilities as well as other parts of the layout. I hope everyone has a Merry Christmas and a Happy New Year.

David

Bremerton Northern December 2021 Flimsy

Click here to read the December 2021 issue of The Flimsy Board from the Bremerton Northern Model Railroad club.

David Yadock’s Dry Gulch & Western Update 8

Article & Photos By David Yadock

Dry Gulch & Western, Update 8

It is now time to travel down the mainline into the town of Dry Gulch. This town is the terminus for the narrow-gauge railroad. As mentioned in the last update Dry Gulch is the last puzzle piece but had to wait for completion while all the other sections were worked on and the branch line was realigned. The area has a small business district and a few industries. A small two-stall engine house provides facilities for minor locomotive repair and servicing. A tiny turntable provides for locomotive turning. In this update we will specifically examine the access hatch area.

Photo 41 shows the Dry Gulch area before scenery and branch line realignment was completed. Yes, a station, turntable, and small coaling tower were there but the scenery was lacking. You will also note in the center of the photo a large hole directly behind the 6-dome yellow tank car! The citizens of Dry Gulch petitioned the layout owner to remedy this problem since it was a danger to the public. The hole is actually a large access hatch that is needed to service the track and switches located at Potter Flats, Raade Springs, and the interior portion of Dry Gulch. The access hatch is about 22 inches by 36 inches and is another vertical lift type of hatch.

Photo 42 is an arial view showing the hatch in the closed position. A lot of care was taken to hide the edges of the hatch. Since the hatch can’t have an odd trapezoidal shape it made it difficult to blend in the edges and seam. Careful placement of fencing, guardrails, and shrubbery helped hide the seam along the front of the hatch. The sides of the hatch did not require much effort, they are hidden from view by the other portions of the layout. The back side of the hatch was also difficult to hide. I have found it best to have access hatch holes with odd shapes, that allows them to be hidden much better. Of course, sometimes this can’t be done.

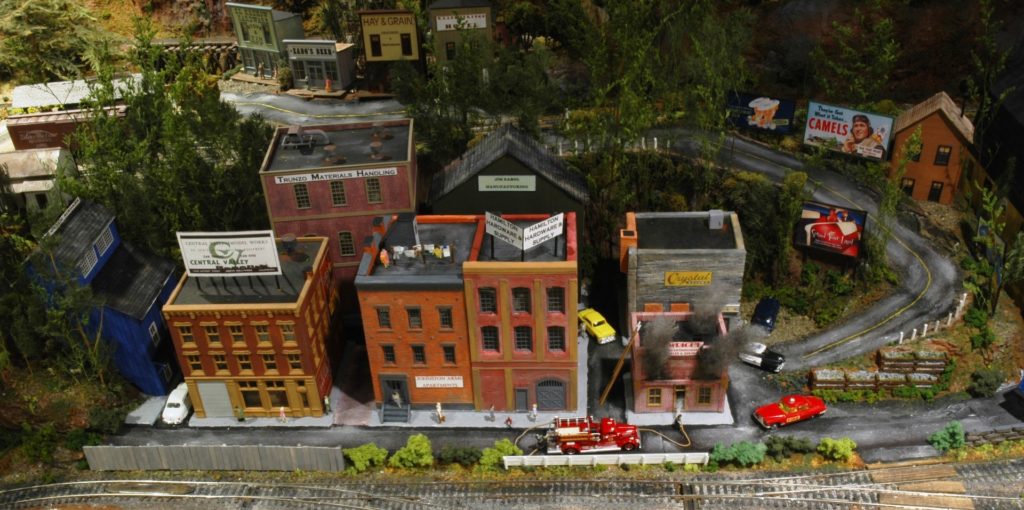

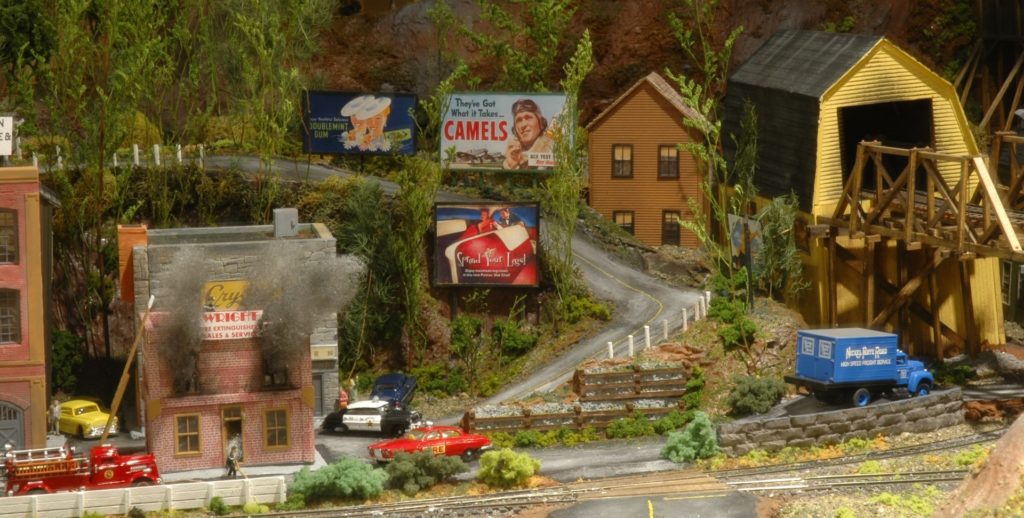

Photo 43 shows an up-close view of a couple of the businesses that cover the hatch. All the buildings have interior lighting. Wright’s fire extinguishers building has some special flicker LED lighting installed. Greg, you should know better than to place oily rags next to open flames! The police car and fire chief’s car roof lights also function. Note the curved roadway, retaining walls, old-style wire guardrails, and multitude of billboards to help add visual interest.

Photo 44 shows another view of the structures. Some of you will note the names of the structures. Greg Wright was poked fun at with his structure, I couldn’t resist it. JJ Johnston is the landlord of Johnston Arms apartments. Both Fred Hamilton and Jack Hamilton can fight over which side of the building belongs to them! Which one of you handles the hardware and the supply? Jim Sabol builds something in that large green structure. Trunzo Materials Handling is named after Jim Trunzo. He is head of the local Pennsylvania Railroad Technical and Historical Society chapter. Most of the structures are from kits, but there are a few scratch-built structures as well. All of this scenery was placed on a rigid foam base and attached to an L-shaped sliding lift mechanism. The weight of the hatch is about 15 pounds, so it is easy to operate.

Photo 45 shows the back of the hatch, looking from Raade Springs. Trees, shrubs, and a small ravine help break up the seam of the hatch. Natural features such as small ravines can help hide or break up the straight line of an access hatch. Small hills or rises in land can accomplish the same.

Photo 46 gives you another view of the structures that are in Dry Gulch and Raade Springs. You will note just how close these towns are in relation to one another. A road and careful placement of trees helps hide the fact that they are only a few inches away from each other. Must be wash day at the apartment complex! Ed Liesse provided the Central Valley billboard sign. It is from a 1960’s era NMRA convention handout. I made a photocopy of it and made the roof sign.

Next time I will provide a photo of the hatch in the raised position to give you an idea of how the edges were hidden. Also, we will look at the changes happening with the Dry Gulch foreground area. As of this point it is still a work in progress. Some of the features have been installed, but most of the ground cover and especially the two-stall engine house is still waiting for final placement. I was hoping for it to be further along, but a shoulder injury has slowed its progress. Have a safe and blessed Thanksgiving.

David

David Yadock’s Dry Gulch & Western Update 7

Article & Photos By David Yadock

Dry Gulch & Western, Update 7

All of you that were able to see my Zoom layout tour on September 11th will know what this update is all about. I will go over some of the subtle changes that are in and around the Potter Flats/Raade Springs area. Some more scenery was added along the mainline. Trees were planted and Raade Springs was completed. That scene was finally joined in with all the other areas. The last piece of the puzzle is the Dry Gulch access hatch, you may see it hovering up in the air in some of these photos. That access hatch has been a slow work in progress but once completed it will allow the scenery to be finished off in the Dry Gulch peninsula area.

Photo 34 shows what Raade Springs, and the surrounding area looked like prior to adding scenery. I only had a small station placed in the town. The branch line that serviced Raade Springs was never really operational and most of the track was buried in tunnels. This was not good for operational capabilities, so this area was never fully developed. A remedy for the buried track was needed if I was to apply scenery to the entire area. The track to Raade Springs was relocated and now most of the track is no longer in tunnels.

Photo 35 is a nice view looking down the mainline that also serves as a branch line to Raade Springs. Potter Flats is on the left while Raade Springs is toward the right. The large yellow barn-like building on the right is a coal pocket that is accessible via the town of Wapwallopen on the branch line. A nice stand of trees has been planted to act as a view block.

Photo 36 Raade Springs is a small hamlet served by the branch line. It has two mining operations. The Cantby mine and the Higotta mine are both located on one side of the town. The Higotta mine ore bin is placed on the combination branch line and siding. This siding leads directly into Dry Gulch through a short tunnel just out of the picture by the ore bin. This becomes a dual-purpose track for either branch line or siding use during operating sessions.

Since Raade Springs is placed on a very narrow strip of real estate I cantilevered three structures so that they hang off a short cliff. This allowed me to place the buildings in front of a small road. The rest of the area was built up and many wooden retaining walls are placed in the area. This gives the location a mining town charm. You can see the main support for the Dry Gulch access hatch just above the ore bin.

Photo 37 Here you can see how small an area Raade Springs occupies. To the right is Higotta mine and its ore bin. In the photo at the top right is Cantby mine. To the left of A. Oster supplies is the vertical support for the Dry Gulch access hatch.

Photo 38 Cantby mine is next to Higotta mine and features a forest the was logged off years ago to supply wood for the mine. Opportunistic trees have taken over where the forest was cleared.

Photo 39 Give a clear view of Higotta mine with Cantby mine in the background. You can also see the many wooden retaining walls placed in the area. Floating in the top left portion of the photo is the Dry Gulch access hatch! This hatch gives me complete access to Potter Flats, Raade Springs, a good portion of Wapwallopen, and the backside of Dry Gulch.

Photo 40 shows the other side of Higotta mine. The little green building in the center bottom of the photo is Woody’s Gun shop named in memory of Woody Matthews, longtime member of the 4D. That covers this area of the layout.

Next time we will finally have a look at Dry Gulch and all the changes that have occurred over the past few months. This entire area of the layout has been akin to assembling a large puzzle. There have been many “mini” scenes needing to be tied together. The last piece of the puzzle is Dry Gulch and its scenery. Most of Dry Gulch’s scenery had to be put on hold till all the other scenery was in place.

David