Article & Photos By David Yadock

Dry Gulch & Western, Update 3

As mentioned at the beginning of my photo layout series in the Grab Iron, the photos presented in this series are more records of progress rather than glamour shots. Since the outbreak of Covid-19 and the “stay at home” orders I have been working on many Dry Gulch & Western projects when not at my day job. I have mainly concentrated my efforts at completing scenery in the central portion of the layout, an area that is roughly 10 feet by 14 feet. This section of the layout had some track issues that needed modification. One major problem was the branch line running out of Dry Gulch. The original plan was to have a separate line proceed to the tiny mining town of Raade Springs. The major problem was that most of the line was buried into very long tunnels. Hidden track is never a good way of doing things and changes had to be made!

It took a long time to come to the realization that the track needed to be changed and that is why scenery in this area languished. What should I do? Remove the tunnels? Daylight the tunnels? Change the branch line? There were many choices, but I chose to re-align the track. It created some challenges along the way. First, I removed all the track in the very long tunnel. This tunnel went from one side of the Dry Gulch peninsula to the other (about 10 feet). Next up, I created a crossover track that connected the mainline that goes to Dry Gulch with a portion of the old original branch line track. Only a hole in the mountain needed to be created to carry the track from the crossover. Luckily both tracks were at almost the same elevation and hidden from view by that mountain. This crossover track is on the mainline located between my town of Gornitzka Crossing and Dry Gulch. Since the crossover is hidden, the branch line track now appears to be its own stand-alone track. This track comes out of a wooden tunnel portal on its way to Raade Springs. Operationally, this works much better since only a small portion of the branch line track is hidden in a tunnel. Another bonus is that I am able to use one small section of track for two purposes (branch line and mainline). The other feature is that I now have a spot for a new town on the layout. It will have its own station and will feature a couple of small industries. This new town is physically separated from Dry Gulch because of its elevation yet it’s buildings will blend in with the town of Dry Gulch. This new town will increase the operational capabilities of the layout without too much additional scenery or space. This use of space is something to consider with layouts that have size constraints.

The new town is called Wapwallopen (named after a small hamlet in Pennsylvania). It has two sidings and a run-around track. I admit the improved branch line was a major change on the layout that required quite a bit of work. The control panel needed modifications. There were 4 turnouts added to the layout along with new sections of track. Two straining beam wooden bridges were constructed to carry the track to a newly constructed coal pocket. Several structures still need to be completed in this area. All the track has now been ballasted and tested. This new branch line will allow trains to originate out of Dry Gulch, something that was previously not done. Once all the scenery is completed even more trains will be able to use Dry Gulch as their starting point. This will create a multitude of operational possibilities.

For your viewing ease I will be placing “before” and “after” photos of the newly completed areas. This will allow you to compare the old with the new scenery/additions without having to go back and view the older Grab Iron entries I have made.

Photo 11 shows the area where the new town of Wapwallopen will be situated. In this “before” photo a new town will be located approximately where the Borden’s Fine Cheeses reefer is parked. That flat area was built out and extended to allow for a run-around track and two additional turnouts. Some room was created for additional structures.

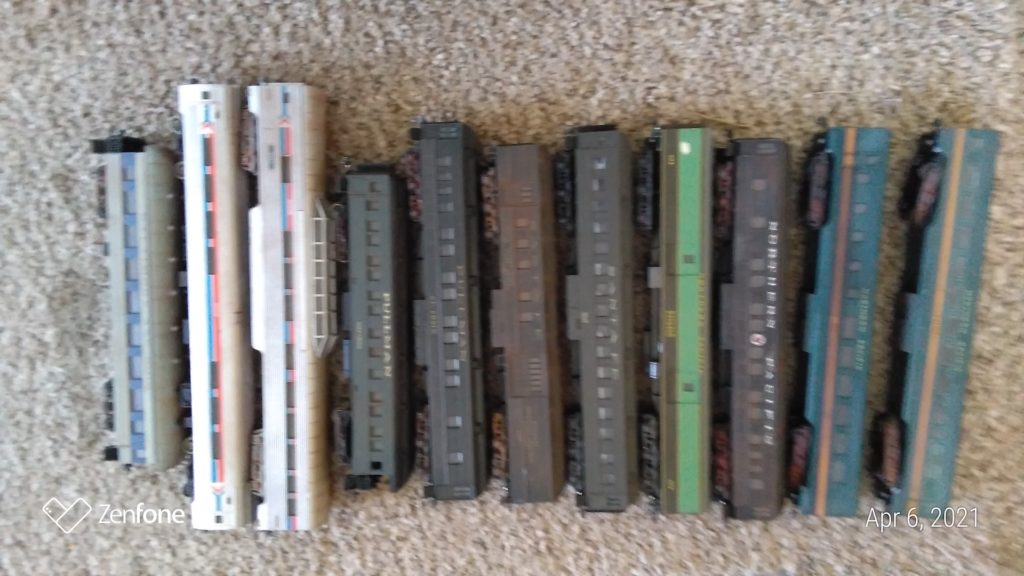

Photo 12 (another before photo) gives the overall view of the area prior to the changes. This photo shows the limited working space in this area. In a few square feet two bridges were installed, a run-around track, and several structures added to create a town. The mountain that is behind and to the left of the red, white, and blue reefer in this photo hides the crossover connecting the mainline with the branch line.

Photo 13 shows a close-up view of some of the new track and turnouts. I added more plywood to give some needed real estate for future structures. Woodland Scenics wall units were added to finish off the front height gap that was created. In this photo you can see the run-around track and one of the straining beam wood bridges. The bridge was a highly modified Campbell kit that carries one of the turnouts for the run-around track. The track then continues on to yet another straining beam bridge and then finally to a coal pocket.

Photo 14 is an odd photo, but it shows half of the new crossover that has been added to the mainline (north of the roadway). The rest of the crossover is in the mountain. This crossover is directly behind the mountain in the center of photo 12. To give a frame of reference for this photo, the photographer (me) was standing on the Ellison yard tracks hovering just over the forest above Gornitzka Crossing. If you look at photo 11, I would be just in front of the small waterfall cascading down the mountain along the back wall pointing my camera directly across the room. I admit, I will probably never take a photo from this vantage point ever again! When this photo was taken there was still some scenery to complete by the crossover and vehicle roadway.

Photo 15 shows a closeup of the tunnel entrance. The branch line is the track closest to the front and is one leg of the crossover from photo 14. The next track is a long siding that curls into the mountain and can be used store several freight cars for switching or storage. The next track in the photo is a siding coming off the small yard in Dry Gulch. This track is about 4 inches below the branch line tracks. That will be a loading area for cut stone. Construction of a stiff leg wooden derrick has begun and will be placed next to that siding. A small station will be located by the turnout at the bottom center of this photo.

Photo 16 shows an overall “helicopter view” of the area. There isn’t very much space, but it will make for an interesting section of the layout. The run-around track will allow for locomotives to complete switching of businesses. Here you can see the two bridges and the coal pocket. The original branch line track to Raade Springs is directly behind the coal pocket. This portion of track is still used while most of the other track that was buried in the mountain has been removed. Only some more trees and structures to be added to the area, then it will be complete.

This new portion of track has changed the way trains will function out of my layout’s namesake town. It will give new operational challenges as well as opportunities. This just goes to show you that a layout must remain fluid and can be changed at any time. Next time I’ll give you a view of some more new scenery additions to the Dry Gulch & Western.

David