Al Carter / Photos By Al Frasch

Clinic Chairperson Rich Blake welcomed all to our December clinic. He gave a brief rundown of upcoming model railroad related events in the Pacific Northwest, noting that the Fourth Division’s Pacific Science Center show will be held on MLK weekend, January 18-20 2014, and volunteers are always needed to help. Check the Grab Iron for more details.

Jack Tingstad reported that his annual open house over the Thanksgiving weekend was another resounding success – he estimates several hundred visitors came by to see his Cloud City And Western railroad and donated over 1000 pounds of food to the “Gifts From The Heart” food bank in Coupeville.

Al Carter gave a brief rundown on the upcoming PNR Convention to be held June 18-21 in Tacoma, WA and encouraged folks to attend. A great “warm up” for the NMRA National Convention to be held in Portland, OR in 2015.

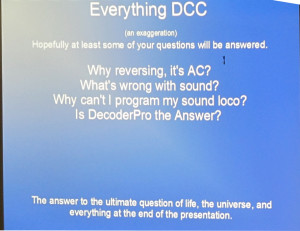

Ted Becker was the featured clinician for the evening, with a program titled “Everything DCC” – which was a general overview of the DCC method of operating model railroads. Ted had asked earlier for people to send him questions that he could answer to the whole group, but the response was, er, underwhelming, so instead he made up his own questions.

Among his “questions” was “What Is Wrong With Sound” (DCC sound decoders)? His answer, and this author is in agreement, is that sound decoders “out of the box” are generally too loud. When several sound equipped locos are running, they are filling the room with sound that becomes hard to distinguish. In Ted’s opinion, the decoders should be turned down so you hear the loco when it passes by you, but doesn’t overwhelm the room.

He also discussed the “keep alive” features that some DCC circuit boards are including these days (that keep the loco running when it encounters a brief dead spot, like a frog) – these keep alive features can create some programming issues. ed mentioned some work-arounds.

Ted also discussed the various ways to program a locomotive, and mentioned the new BLI Address Changer (but he hasn’t had time to review it yet), and the Sprog unit (from England). Ted then went into a brief overview of Decoder Pro, and brought it up on the computer and screen so we could all see how easy it is to use. Ted had brought a small test system with him and actually used Decoder Pro to make some changes to the loco.

Ted suggests for help using Decoder Pro, you have several options – you can peruse the JMRI pages on the web, type questions into a web search engine, download the full manual, or join a Yahoo Group on JMRI and/or DCC systems. Plenty of options are available.

As there was a little time left over, Ted gave a brief ad-libbed overview of JMRI’S Operations software and how it can be utilized to make operations orders and switch lists. For more info on the JMRI Operations Software, see: http://jmri.sourceforge.net/help/en/html/apps/PanelPro/PanelPro.shtml

The January 2014 Clinic starts the new year off with a presentation “Be A Rock Star – Make and Take Rocks” by Jim Tartas on using the Joel Bragdon Geodesic Foam/Resin method of making rocks. I’ve seen Joel Bragdon give demonstrations on this method before and it is certainly an intriguing way to produce some great looking rocks without all the mess of using plaster or hydrocal. Don’t miss this clinic!