Text & photos by Roger Johnson

The April 2015 Mount Vernon Clinic of the 4th Division, PNR, NMRA was attended by 21.5 souls. Ted Becker opened the session with words encouraging NMRA membership, echoed by Al Carter.

Announcements reminding us of upcoming events included:

- Olympia area layout tours Saturday May 16th

- 4th Division Spring Meet in Bellevue Saturday June 6th

- NMRA National Convention in Portland OR August 23-29

Tools of the Month discussed were the use of scalpels instead of hobby knives for work bench projects and small dipping cups (we won’t tell here where Ted got these) for mixing small paint batches.

Bring & Brag items featured (please see photos below):

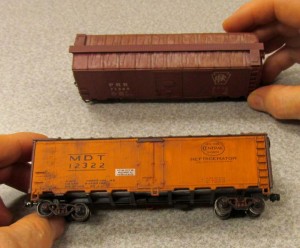

- Another of Paul Koren’s fine resin box cars, this one a Nickel Plate model. It was very nicely painted with TruColor paint sprayed on with an airbrush with decals depicting the early days of the Nickel Plate Road graphics.

- Ivan Musinich brought a pair of McKeen gasoline motor cars, the prototypes of which we built by the McKeen Motor Car Company in the early 1900’s. McKeen cars had a distinctively nautical look with sharp bows, rounded stems and round windows that looked like portholes. The smaller model car pictured was scratch built by Ivan’s brother around 1955 from an article in Railroad Model Craftsman. It is now DC equipped and compatible. The larger 55’ car is a Ken Kidder model found at the Monroe show. Ivan restored it to closely model the car Northern Pacific purchased in 1909, equipping it for DCC with a TCS decoder.

- Two nicely weathered flat cars by Curt Johnson, on one of which was a steam winch kit built by Curt and Iver Johnson.

- Mike Pettruzzelli brought a very nice sound decoder equipped N scale Shay.

- Rick Troyer displayed what is believed to be a fire instruction car painted in a Great Northern Pacific Railway scheme. One side is all red and the other is green with flames all along the bottom. If you look closely at the familiar Goat herald you will notice that the background is the red and black NP monad and the goat has transformed into a dog. Rick would welcome any information concerning this car, either model or prototype.

This month it was decided to go with several mini clinics so the evening’s program consisted of five brief presentations (please see photos below):

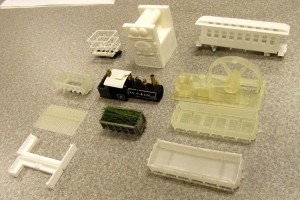

- First up was MMR Nick Muff telling & showing us how easy and inexpensive it is to delve into the world of 3D printing. With slides, oral explanations and sample items passed around we learned about Shapeways, a 3D printing company, and Autodesk 123D Design, free downloadable software for 3D design. One designs the desired item using 123D and then uploads it to Shapeways. After analyzing the design for printability Shapeways will print the item, generally for $3 to $5 per unit, depending upon size and complexity. Although 3D printers are available for consumer use, the sophistication and quality of the Shapeways output results in superior items. And Shapeways handles all of the maintenance and repairs, if any.

- Next up was Tom Buckingham demonstrating construction of spline sub roadbed. With a small piece of bench work with risers he, with Al Carter assisting, built a sweeping 5± foot curve of roadbed in just a few minutes. Simply stated it requires long thin strips of wood (Tom used three) separated every few inches by small wood blocks, all glued together. What starts out as rather wobbly strips of wood winds up quite rigid and suitable for model railroad sub roadbed.

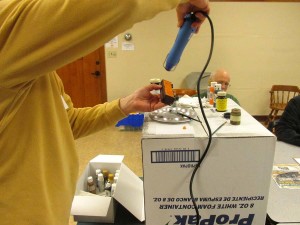

- Bob Stafford then demonstrated is technique for quickly weather rolling stock using several acrylic craft paint colors and mixes thereof. He uses both washes and dry brushing and to speed the process employs a small heat gun to dry each coat, enabling him to add coats after only a very few minutes. He keeps an old sock handy to wipe up any excess liquid or oooopses. Thinning and brush clean up are done with windshield fluid to avoid droplets forming and for quick drying.

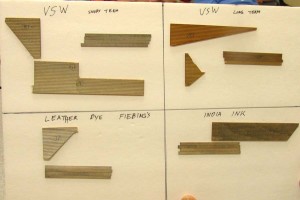

- Ted Becker followed with two topics, the first of which was a progress report on his experimentations for staining wood. He had tried two vinegar and steel wool “soups”, one of which steeped for about ten days and other only a day or so. He also used alcohol based leather dye and diluted India ink. He said only alcohol based leather dye should be used to avoid warping. To emphasize the point he lifted a bottle of alcohol out of his project bin but it turned out to be a half filled liquor bottle. (These experiments may go on for a while.)

- Ted also demonstrated dry brushing for weathering shingle roofs, both the uniform laser cut type and the more rustic Campbell’s variety. Especially effective, in this writer’s opinion, was an octagonal peaked roof on which Ted had daubed various weathering type colors on the Campbell paper shingles.

- Wrapping up the evening was Al Carter demonstrating dry sponging weathering and paint fading on brick modeled structures. He uses some small wedge shaped sponges available in the cosmetic department at drug stores and supermarkets.

- Al also had a couple of demo samples showing a way he developed to mount under layout Tortoise switch machines without having to get under the layout. The Tortoise is mounted on a rectangle of hardboard the same thickness as the cork roadbed and replaces the cork for about three inches. A rectangular hole is cut in the sub roadbed into which the Tortoise is inserted with the hardboard rectangle mating with the cork roadbed at each end.

Next month’s clinic will be a presentation by Robert Gilbert, of Tesoro Petroleum, talking about Tesoro’s offloading facility / rail operations at its March Point refinery. For location and hours, go to the 4D Clinics page.

Bring & Brag photos:

Mini Clinic photos:

In my defense, the liquor bottle was empty and was empty when I got it. To be clear the shingles are colored BEFORE applying to the roof to get the row-by-row effect.