Roger Johnson, photos by Roger Johnson and Bob Gilbert

Twenty-six folks attended our last clinic of the season to enjoy an excellent program (see below) and some delicious brownies baked by Paul Koren’s wife. Thank you Mrs. Koren! Ted Becker, our MC, once again opened with encouragement to join NMRA, the sponsoring body for our meetings through the 4th Division of the Pacific Northwest Region

Announcements reminding us of upcoming events included:

Tool of the Month: Al Carter brought our attention to a web site that has the free graph paper generator, where you can adjust the graph squares to represent a scale foot in your given scale, very handy for scratch builders. The link to the web site is http://www.incompetech.com/graphpaper/lite/

Bring & Brag items featured:

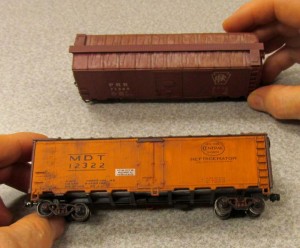

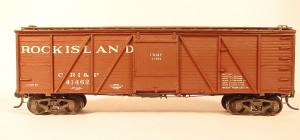

- Two more of Paul Koren’s fine resin box cars

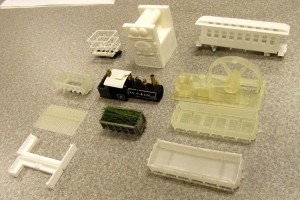

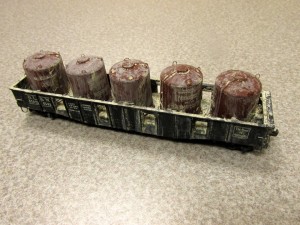

- Nick Muff displayed more of his 3D printed sugar cane cars by Shapeways

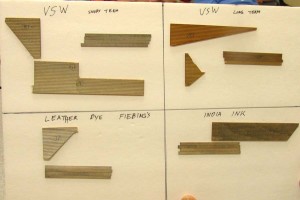

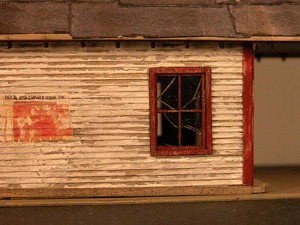

- Roger Johnson showed a color palette displaying the five brick colors he uses

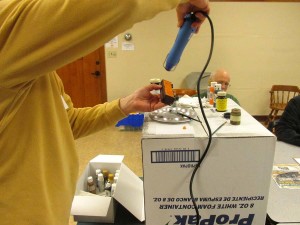

- Roger also displayed the home made hot wire foam cutter he made for under $15

Our program for the evening was about Tesoro Logistics’ crude oil rail off loading facility on March Point, Anacortes. R. L. (Bob) Gilbert did an excellent job telling us about the construction and operation of Tesoro’s rail offloading facility at its March Point refinery. This writer was so interested in what Bob had to say that he didn’t take notes until he got home. So any meandering and/or inaccuracies are the fault of the writer, not the speaker.

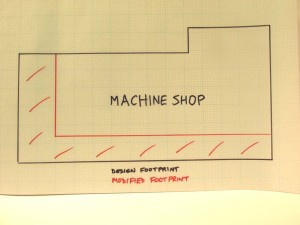

The facility was completed in September of 2012 located at the bottom of the slope on the west side of the point. The site originally proposed was higher up the slope but it was determined that there were some wetlands in that area which could have been mitigated but the alternative site was determined to be the best option to be able to proceed in a timely and economically feasible fashion.

The facility consists of a concrete pad 1,600’ long by 110’ wide lying in a NNW to SSE orientation parallel to the Fidalgo Bay high water mark 200’ to the west. There are four tracks built into the pad, each able to hold 25 cars or a 100 car train. Bob described a very complicated and comprehensive infrastructure under the pad for the collection of the crude oil, control of emissions and capture of any oily water (he claims it rains around there occasionally) that may accumulate. These include piping, wells for inspection and testing, pumps, etc., the details of which were somewhat dizzying to this writer. Under it all a single piece rubber diaphragm extends the full 1,600’ by 110’ facility to catch anything that may escape the more sophisticated capture devices above.

Under normal conditions, one train arrives each day, hauled to the refinery site by Burlington Northern Santa Fe. A train can be ready to roll out of the refinery within 12 to 18 hours from the time it enters. At the gate, the BNSF crews are replaced by crews from Savage Services. These folks conduct the rail and off loading operations under contract with Tesoro. They bring the train in, break it into 25 car cuts and back them into the offloading facility. They then proceed to offload the crude via 4” hoses attached to the underside of each car with the oil draining out by gravity into a 36” recovery line underground. The vent is opened at the top to avoid a vacuum forming inside the tank car. Every other car is vented with emissions from the emission recovery system via an emissions recovery pipe that leads from the underground recovery line to the car’s top vent. The other half of the cars take in regular atmospheric air to equalize the pressure.

Once enough oil has been collected, pumping it from the offloading facility to the refinery (7,000’ distant and 200’ higher) begins. There are three pumps, each rated at 2,500 gallons per minute (GPM). They are brought on line sequentially to pump at the rate of 7,500 GPM when all three are running at 100%. This flow rate is essentially equal to 10,000 barrels per hour (BPH). One tank car holds approximately 680 barrels (42 gallons/barrel). Thus a 100 car train carries 68,000 barrels. At a rate of 10,000 BPH the train can be emptied in approximately 6.8 hours.

There is also a team of UTLX people on site to do any repairs or maintenance a tank car may require. If repairs cannot be completed soon enough to return the car to its train there are contingency cars on site for replacement, with the repaired car put in the contingency group when repairs are complete.

As noted above, a full 100 car train is carrying upwards of 68,000 barrels or 3 million gallons of oil. What is called West Texas Intermediate is a common benchmark used to gauge the prices of various types and grades of crude oil. The current value of WTC is approximately $52/barrel but Bob indicated that the oil they bring in is priced somewhat less than that. He was understandably vague on Tesoro’s actual cost. This writer did a hypothetical calculation using a cost of $40/barrel resulting in cost of a train load at the gate of slightly more than $2.7 million.

With regard to environmental safety, Bob indicated that they have had zero spills and zero injuries since inception of the operation in September 2012. As an indication of the extent to which Tesoro goes to avoid environmental damage, before the cars are drained, each one gets a hand placed fiberglass drip pan placed underneath it to catch any stray drips from the fittings. On a final note, while recent tank train derailments that have been prominent in the news do not pertain to the refinery itself, the over the road transportation is obviously part of getting the oil from the ground to our gas tanks, so it is of concern to Tesoro and other producers. Bob pointed out that while improving the integrity of the cars is important, the most important thing is to eliminate the derailments. No matter how a tank car is reinforced, if it hits the ground at 50+ MPH there is probably going to be trouble (my words, not Bob’s).

Thank you, Bob, for an outstanding presentation.

Our speaker Bob Gilbert of Tesoro Logistics

Tesoro Logistics’ March Point crude oil rail off loading facility

This was the last clinic of the season for the Mount Vernon group. A total of 140.5 (an 8 year old son of one of our adult participants) people attended the eight clinics for an average of about 17.6/session. Our email list has 56 addressees on it and we have another 17 names of folks who just drop by from time to time, including a fellow from Texas. A schedule of interesting and informative programs will be developed over the summer months and announced in the next newsletter in mid September. Have a great summer!