Article and Model Photos by Rich Thom, Speeder Photos from Rich Blake Collection

28 modelers filled the meeting room at the Summer Hill facility in Oak Harbor for the SV&W Clinic’s February meeting. Clinic Chair Rich Blake introduced new attendee Nick Kelsey, an Fn3 modeler, who just moved to Coupeville. (Editors note: Fn3 is 45 mm gauge track, same as G, with a specified scale of 1:20.3; G is 45 mm track gauge, but covers multiple scales running on the same track.) Welcome, Nick, and we all look forward to seeing your new outdoor pike under construction very soon. Rich reminded everyone of the upcoming UNW train show in Monroe at the end of this month, and the Sn3 Symposium in Bellevue April 16-18. Rich also called attention to the NMRA election of national officers underway, and urged all members to cast their votes. Susan Gonzales gave advance notice of a potential trip next clinic season to the Northwest Railway Museum in Snoqualmie, to get an inside look at the NP 0-6-0 switcher that is being rebuilt there.

Next up was “Show and Tell,” and three fine models were in the spotlight tonight.

Curt Johnson described the HO-scale flat car with load that he and his dad Iver Johnson just completed. The load is a Jennings Log Skidder, a kit manufactured by Scale Structures Ltd, Broomfield, CO. The Jennings Lumber Company bought several skidders from Nevada Iron Works and Foundry, the prototype for the model. The instructions weren’t in the box, and Iver and Curt couldn’t find them on-line, so they had to build the skidder a cappella. The car deck was built board-by-board, the spools of cable and water tank were scratch built, and additional details were added to the skidder.

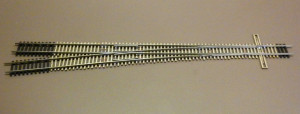

John Mann passed around an N-scale, no. 8 turnout that he fabricated with a Fast Tracks jig. (Your photographer failed to remember to place a coin in the photo, so readers will need to trust us: it’s N-scale.) The Code 55 rail required some delicate soldering, one of John’s special skills. John used a no. 8 double-crossover jig with which, he pointed out, one can build double- or single-crossovers as well as left- and right-hand turnouts.

Tom Hawkins displayed his HO-scale, brass PFM Ma & Pa 2-8-0 which has had DCC and sound installed by David Clarke. Tom helped with the project but credited David with most of the work. David also painted and decaled the model. Despite retaining it’s original open-frame motor, the Consolidation runs beautifully.

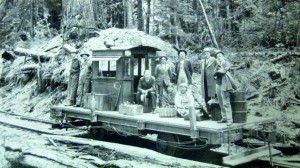

Rich Blake then gave the evening’s presentation, Evolution of Logging Speeders in the Pacific Northwest. One of the most important vehicles to Northwest logging operations was the speeder. During the era when there were more rails than roads in the woods, the speeders became the versatile vehicle of choice to get people and equipment to remote areas along the lines. Speeders functioned not only as MOW (maintenance-of-way) vehicles, but also as crew transport, ambulance, school bus, fire watch, grocery getter and light locomotive from steam days well into the modern era.

The obvious predecessor to the speeder was the handcar, used by section gangs from 1850 to 1900 for track maintenance and hauling tools. It is estimated about 13,000 were in use. After the turn of the century, gas powered cars began to replace handcars, although on the Class 1 roads they were always primarily for track inspection and maintenance.

Logging railroads had quite different requirements. Not normally utilizing sections and gangs like the mainline railroads, they maintained track as needed using whatever locomotives and men were on hand. One of the biggest burdens of the logging railroad was the large number of people necessary to support logging operations, and getting them in and out of the woods. In the early days, logging locos were used to transport people on whatever rolling stock they had on hand, usually skeleton cars and flat cars, which obviously exposed the crews to the elements and danger. Sometimes closed crew cars or passenger cars were used, built or bought second or third hand. However this didn’t solve another problem: it was slow going. 15 mph for a typical geared loco was really flying along. Moreover, using logging locos to move people was not a good use of what were typically the most expensive assets on the property. The use of camps in the woods closer to the working areas helped, reducing travel time, but the camps were expensive to maintain and equipment-intensive. Hauling supplies to the camps, or switching cars around the camps, still took a logging loco away from its more important work. What was needed were “logging speeders”, faster than the logging locos and more powerful than the small gas speeders on the mainline railroads.

Enter the Skagit Steel and Iron Works, established in Sedro Woolley WA in 1902 as the Sedro Woolley Iron Works. Originally offering heavy repair service to the logging operations, at a site more convenient than Everett or Bellingham, its business expanded until, in 1921, the company decided to develop a line of gas powered speeders optimized for the special needs of the loggers. As a hedge against possibly soiling the company’s reputation in the venture, it spun off the Motor Appliance Corporation (MAC).

After first marketing a Fordson Tractor powered donkey engine, MAC moved into larger railroad equipment with the 4-40 rail car (Figure 4). The car had an open deck with a one man “telephone booth” at the front end. The designation 4-40 stood for 4 cylinder and 4000 pounds of tractive effort. The 4-40 was an immediate success. They were powered by a 40 hp to 66hp Model YTU Buda gas engine and weighed about 6 tons; the 8 x 20 deck had a load capacity of 5 tons. With a 5 ton load, they could cope with a 10 percent grade. The beauty of these speeders was they were heavy enough to switch a log car or two, or haul the crew to work. Other models followed, the 6-60 for heavier hauling, and the 4-20 focusing on crew transportation. MAC speeder production continued through 1936.

In 1933 a competitor emerged, the Gibson Manufacturing Co. founded by Henry Gibson and located on 1st Street in Seattle (the building still exists). Gibson recognized the need for larger vehicles (such as in Figure 5) to haul ever-larger logging crews, and developed three models: 12 ft/30 man, 14 ft/40 man, and 18 ft/55 man versions. The Gibson speeders, like the MACs years earlier, were an instant success. By 1939, wood bodies were replaced by steel. Even a 24 ft/65 man model with a fully enclosed body and full controls at both ends of the speeder for driver visibility was produced. In 1946 Gibson, in partnership with Hayes Mfg., built the “Cadillac” of speeders, CanFor’s No. 121, a monster 40 feet long which seated 90 loggers and could zip along at 40 mph. In its 20 years of production, Gibson built about 300 speeders, with its last models hauling 90- 100 people. Henry Gibson passed away in 1953 and the company closed.

Just over the border in Canada, the Westminster Iron Works, an old company established in New Westminster BC in 1874, moved into the logging speeder business for BC logging operations, producing many speeders, some similar to MAC products. Many of the British Columbia speeders featured cupolas for driver visibility, a design not common in the US. One exception was Simpson Lumber No. 117 (Figure 6), a modified Gibson speeder.

As rail logging gave way to truck logging, so went the hard working speeder, replaced by the company pickup truck. Their utility can never be forgotten and their contribution to the many logging operations was instrumental to their success.

Rich showed photos of many survivors in Washington, California, and British Columbia.

In the modeling world, speeders currently require kit-bashing or scratch-building. Several power drive units are possibilities, including NWSL Flea Drive, which one might find on eBay. Box-cab types are easiest to construct so that the mechanism, decoder etc. can be hidden. MAC-type open-deck types will require the most ingenuity.

Figure 7 shows one of Rich’s current projects, modeling a MAC speeder in On30. The flatcar is a Bachmann On30 18-foot car that is being used as a template for a scratch-built chassis. The cab is a resin casting from Boulder Valley Models for an On30 critter. The chassis drive is a Bachmann HO MOW ballast car. We are looking forward to see how it turns out.

Adding a speeder or two to a logging-themed layout will certainly add to realistic and interesting operations.

Hello,

Can we republish the photo of the Fig 4 Skagit Iron Works MAC 4-40 Speeder in our NMRA newsletter? Alain Kap MMR is doing an article on building a MAC 4-40 and the only other photo we have is from an article in NG&SLG

Peter Bowen

Editor

NMRA British Region

Considering that the photo is just a repost from an internet site then yes! There are a lot of photos of these speeders on the web. Have fun.

Rich Blake

Whidbey Island, WA

Seven years later, the photo of the Jennings skidder will be of enormous help to me. Thanks!