by John O’Connell photos: KCAL-Sky 9, John O’Connell, Ted Becker, Rich Blake

September 8, 2016; Mt Vernon Senior Center

Ted opened the Clinic with a hearty welcome to visitors including Tim Silvas, Jack Vander Hoek, and Dave and Paulette Sitzenstock. We hope you’ll join us again!

Before Ted could get very far into his announcements, the tables were turned and Al Carter usurped the floor to provide some much deserved recognition of Ted’s Golden Grab-Iron Service Award for 2016.

Al read some choice anecdotes from the award citation which ended with heartfelt applause. Click here to read more from the 4th Division website.

Kit Build

As a group the Clinic members expressed interest in constructing a building over the course of several months with the intent of bringing their “work in progress” to each Clinic and sharing. Mike O’Brien brought a variety of kits in three scales, N, HO and O, to choose from. After sign ups were tallied, Mike reports 22 of the 24 present signed up. If you were not at the Clinic and want to participate, email Mike directly at sales@xtrainsmodeltrains.com. Mike expects to bring everyone’s kit to the October Clinic so get ready.

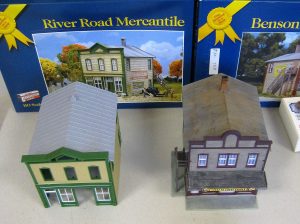

In the spirit of Kit Build, Al Carter showed two examples of what can be done with a plastic kit.

(L) A kit assembled out of the box. (R) Al took a similar kit and detailed it with graphics, glazing and weathering effects using Pan Pastels.

We are all encouraged to be creative, add details and Have Fun!

Tool Time

Ted models a jeweler’s apron…a cook’s apron with magnets sewn into the corners. Small parts fall into the apron not the floor.

What I did this summer

Ted shared some of his projects from the summer. He perfected the fabrication of gooseneck LED lights in HO scale. Ted found the learning curve steep but has the assembly time under two hours (per light).

Ted also shared a wire bending jig and a random LED lighting controller that he programmed in C/C++ using an Arduino board. The possibilities seem endless and the boards are not intended for those with electronics or programming experience.

Al Carter described the ten JPGs he meant to bring on a thumb drive of live railroads he encountered on his 48 days of cruising around the British Isles, Scandinavia, Iceland and into the extreme northern latitudes. We’ll get him to bring them next month!

Al also shared his façade of the Buckingham (no relation) United Freight Lines warehouse. He used Prism Color pens to give the wood siding the aged appearance and chalk pencils to add color.

Al also shared several vehicles he kit bashed. He used Elmer’s School glue for the windshields – much easier than trying to cut and place clear plastic.

John O’Connell shared his attempt to challenge Micro Mark by building his own Air Brush Booth with lights and 12 V exhaust system. His wife still has no idea how much this cost.

The downdraft adaptor was fabricated by Lynden Sheet Metal and the booth itself was fashioned from a plastic storage bin.

Ted shared his paint booth which is self-contained and transportable. It features four 12V computer ventilation fans for tremendous exhaust power.

Al led a general discussion on preparation and painting with emphasis on spray cans. For castings and metal details, Al likes Walmart’s Color Place Primer. For resin models, he gets good results with Sylvan Resin Prep as well as Westby’s Tire Cleaner and for plastic, good old soap and water. Al suggests using a light colored primer, white or light gray, if the finish coat is light colored. Paul Kormen suggests Clean-Rite’s Purple Power industrial strength cleaner/degreaser.

For primer coats, Rustoleum offers a range of colors. And for a final flat finish (perhaps to dull the paint and fix baking powder or other weathering effects) Model Master Lusterless Flat provides a dead flat effect. Other popular products are Rustoleum Matte Finish and Krylon 1301 Flat.

And remember to give those cans a good, honest two minutes of vigorous shakin – that’s why the cognoscenti refer to them as “rattle cans!” Another tip – don’t let cold weather keep you from spray painting. Iver Johnson warms cold spray cans in a pot of warm/hot water which makes them spray much better. Soak, spray, repeat.

Around the Curve

October 13: Rich Blake from the Oak Harbor Clinic will lead the Clinic in the much anticipated “Introduction to Air Brushing” followed by hands on!

November 10: Ted Becker will cover “Sticky Stuff”, a clinic on glues and tape. We’ll also kick off a recurring segment on “My Workspace” wherein a clinic regular will describe in words, pictures, and possibly examples where they model.

For other NMRA events in the area please refer to the 4th Division Grab Iron, online at https://4dpnr.com. If you would like to subscribe to the Grab Iron, go to https://4dpnr.com/grab-iron-overview/.

No Comments Yet