Article & Photos By David Yadock

Dry Gulch & Western, Update 8

It is now time to travel down the mainline into the town of Dry Gulch. This town is the terminus for the narrow-gauge railroad. As mentioned in the last update Dry Gulch is the last puzzle piece but had to wait for completion while all the other sections were worked on and the branch line was realigned. The area has a small business district and a few industries. A small two-stall engine house provides facilities for minor locomotive repair and servicing. A tiny turntable provides for locomotive turning. In this update we will specifically examine the access hatch area.

Photo 41 shows the Dry Gulch area before scenery and branch line realignment was completed. Yes, a station, turntable, and small coaling tower were there but the scenery was lacking. You will also note in the center of the photo a large hole directly behind the 6-dome yellow tank car! The citizens of Dry Gulch petitioned the layout owner to remedy this problem since it was a danger to the public. The hole is actually a large access hatch that is needed to service the track and switches located at Potter Flats, Raade Springs, and the interior portion of Dry Gulch. The access hatch is about 22 inches by 36 inches and is another vertical lift type of hatch.

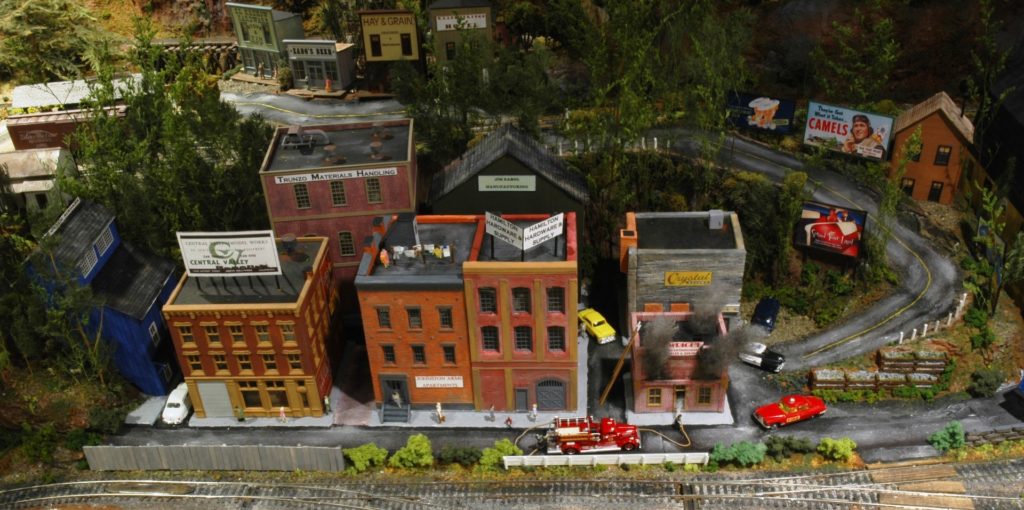

Photo 42 is an arial view showing the hatch in the closed position. A lot of care was taken to hide the edges of the hatch. Since the hatch can’t have an odd trapezoidal shape it made it difficult to blend in the edges and seam. Careful placement of fencing, guardrails, and shrubbery helped hide the seam along the front of the hatch. The sides of the hatch did not require much effort, they are hidden from view by the other portions of the layout. The back side of the hatch was also difficult to hide. I have found it best to have access hatch holes with odd shapes, that allows them to be hidden much better. Of course, sometimes this can’t be done.

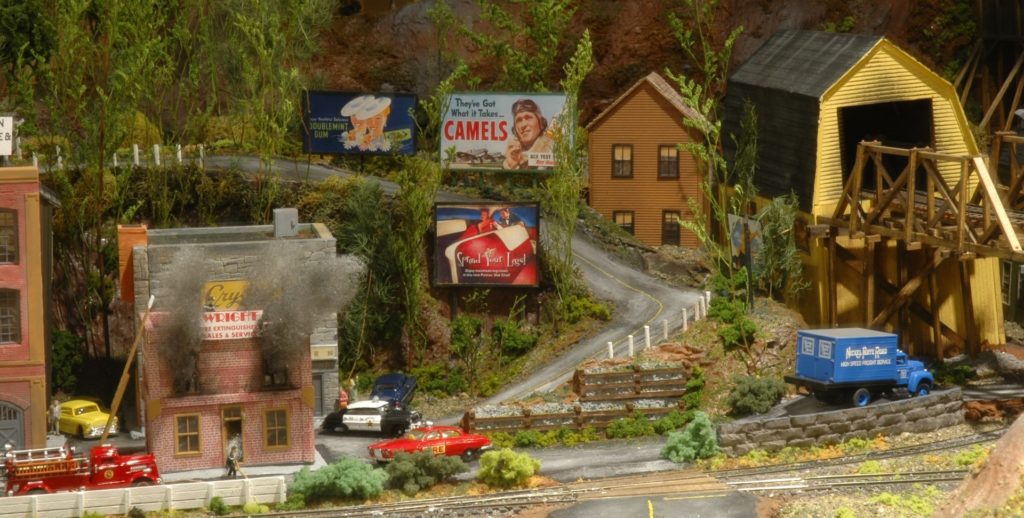

Photo 43 shows an up-close view of a couple of the businesses that cover the hatch. All the buildings have interior lighting. Wright’s fire extinguishers building has some special flicker LED lighting installed. Greg, you should know better than to place oily rags next to open flames! The police car and fire chief’s car roof lights also function. Note the curved roadway, retaining walls, old-style wire guardrails, and multitude of billboards to help add visual interest.

Photo 44 shows another view of the structures. Some of you will note the names of the structures. Greg Wright was poked fun at with his structure, I couldn’t resist it. JJ Johnston is the landlord of Johnston Arms apartments. Both Fred Hamilton and Jack Hamilton can fight over which side of the building belongs to them! Which one of you handles the hardware and the supply? Jim Sabol builds something in that large green structure. Trunzo Materials Handling is named after Jim Trunzo. He is head of the local Pennsylvania Railroad Technical and Historical Society chapter. Most of the structures are from kits, but there are a few scratch-built structures as well. All of this scenery was placed on a rigid foam base and attached to an L-shaped sliding lift mechanism. The weight of the hatch is about 15 pounds, so it is easy to operate.

Photo 45 shows the back of the hatch, looking from Raade Springs. Trees, shrubs, and a small ravine help break up the seam of the hatch. Natural features such as small ravines can help hide or break up the straight line of an access hatch. Small hills or rises in land can accomplish the same.

Photo 46 gives you another view of the structures that are in Dry Gulch and Raade Springs. You will note just how close these towns are in relation to one another. A road and careful placement of trees helps hide the fact that they are only a few inches away from each other. Must be wash day at the apartment complex! Ed Liesse provided the Central Valley billboard sign. It is from a 1960’s era NMRA convention handout. I made a photocopy of it and made the roof sign.

Next time I will provide a photo of the hatch in the raised position to give you an idea of how the edges were hidden. Also, we will look at the changes happening with the Dry Gulch foreground area. As of this point it is still a work in progress. Some of the features have been installed, but most of the ground cover and especially the two-stall engine house is still waiting for final placement. I was hoping for it to be further along, but a shoulder injury has slowed its progress. Have a safe and blessed Thanksgiving.

David

Very nice!

It just keeps getting better and better, David!

What an honor to be named on your railroad. I have a building with your name on it except it’s in a kit to be built. 😁. Love your work.